Calibration and Inspection

Dlook widens the scope of work and adds the Service of Road Tanks Inspecton and Certification to the Services provided.

During the work Safety is number one priority, Inspection of Transportation Road Tanks is a must Especially for LPG Transportation Trucks due to the High pressure Inside the tank

LPG tanks in vehicles must be inspected once the previous inspection is Expired.

The tank needs to have everything from its’ structural condition to emergency pressure relief valves checked to make sure everything’s working as it should.

Once the tank has been inspected – and components replaced if need be – it will be date stamped to confirm another specified service life.

DLOOK IS PROVIDING THE SERVICE AS PER THE INTERNATIONAL STANDARDS AS LISTED BELOW:

- BS EN 12972:2015 (Tanks for transport of dangerous goods. Testing, inspection and marking of metallic tanks)

- BS EN 14334-2014 (LPG equipment and accessories. Inspection and testing of LPG road tankers)

- EN 12493 (LPG equipment and accessories – Welded steel pressure vessels for LPG road tankers – Design and manufacture)

INSPECTIONS DONE ON THE LPG ROAD TANKS

- Inspection Report: Includes General Information of the Tank that is available on the Manufacturer Name Plate, pictures of the Tank condition during Inspection, summery and result of Inspection, Scope of inspection and Client information is mentioned inside.

ANNEXES:

- Hydraulic Pressure Test: The Tank will be filled full of water and Pressurized as per manufacturer Design, Capacity and Test Pressure (Mostly up to 23 Bar) and will be held for 1 Hour. (Period of Inspection is 10 years)

- Leak Proofness Test: The Tank will be pressurized with air up to 4 Bar and the pressure will be held for 5 to 15 minutes. (Period of Inspection is 2.5 years)

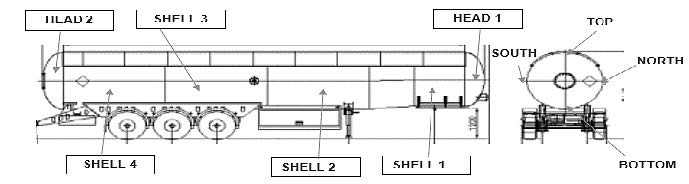

- UT Thickness Measurement: The Tank Material Thickness Measurement should be done by a calibrated UT Machine. Test measurements will be done on 4 points of Each Shell North, South, East, and West as mentioned in the Image.

- HSE Checklist: Indicating all HSE Requirements that should be available in the Tank and Cabin of the Tank

After all Inspections Done, where no leak and Permanent deformation found during the Hydrotest, no air leak found in the Valves and Connections at the bottom and top of the Tank and all HSE and Standard Requirements are met, the Tank will be Certified signed and Stamped ready to be used until next Periodic Inspection.

Tank Accessories:

Every tank has 4 main accessories (2 Pressure Safety Valves, 1 Pressure Gauge and 1 Temperature Gauge) all those accessories should be calibrated and Certified Annually.